Navigating the shift: Your guide to UgoWork’s lithium-ion battery charging infrastructure transition

The material handling industry is now more than ever facing the crucial decision to convert their existing lead-acid battery infrastructure to electric forklift fleets equipped with lithium-ion batteries. This kind of initiative brings numerous advantages, including eliminating the need for battery rooms, frequent handling, water equalization, and the associated risks of dangerous vapors, acid spills, and other health and safety hazards typically associated with lead-acid batteries.

The reluctance to transition from a traditional energy source to Li-Ion electric power often stems from uncertainty and a lack of knowledge of the technology. Numerous businesses find themselves overwhelmed as they attempt to grasp all the necessary information pertaining to the energy transition process, spanning from the installation basic requirements to the final phase when the staff is trained and your MHE fleet is up and running.

A question we often come across regardless of the intensity of operation and fleet size: Where should I begin?

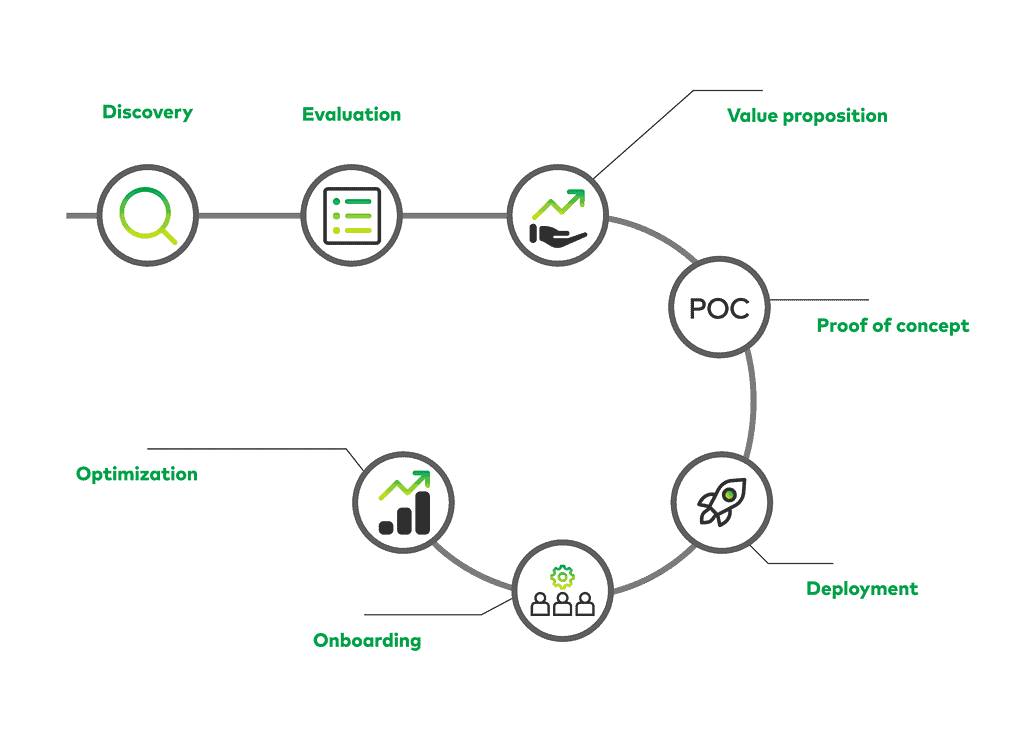

This article will explore the different steps you can expect when looking into a UgoWork lithium-ion battery charging infrastructure, from the first contact to the installation in your work environment.

Upon reaching out to our energy experts, we start with a preliminary assessment that includes:

- Gathering fundamental details about your operations, typical application, environment and company objectives

- Performing a site survey for operations overview and charging behavior assessment

- Delivering suggestions and recommendations

- Providing an initial project plan, including estimates for budget, focus areas and timeline

If the plan meets your objectives and your company decides to move forward with the project based on the energy assessment, we finalize a proposal and provide a full solution approach that includes electrical installation, technical guidance, commissioning, initial training and onboarding as well as maintenance and systems optimization throughout the product lifetime. We will even establish an end-of-life plan.

The energy experts at UgoWork will explain the process and walk you through the entire energy transition.

Our experts are here to ensure a seamless transition to advanced lithium-ion technology, providing support from the initial consultation all the way to the last phase of your energy transition. And it does not stop there.

1. Site survey

The first phase of any project is research. During our initial contact call, we ask questions that begin to frame the scope of your project. This comprehensive conversation helps us understand the full spectrum of considerations and enables us to guide you with recommendations that cater to your specific needs based on goals, budget, space and timeline.

While we can gather a lot of information during that initial contact call, the critical next step is the site visit and evaluation of a wide range of parameters, including:

- Site layout and space constraints

- Electrical infrastructure

- Environment assessment (temperature, cleanliness)

- Operation pattern

- Forklift usage data

- Heavy traffic zones

- Electrical consumption history

- Data transfer infrastructure

We use this data to create a conceptual design so you can make an informed decision about a potential project.

2. Energy assessment review and recommendations

After the on-site assessment, our team meets with you and other relevant decision-makers to explain in detail the key takeaways of the energy assessment along with recommendations. This is the time to ask and go over questions you may have about the process.

Based on your reality and environment, there may be more than one option for configuring the infrastructure to support your industrial truck fleet. We may be able to recommend a phased approach to optimize real-life results as you build your ESG commitment or scale the transition throughout your plant. And there may be opportunities to save money down the road through a charging station mapping that anticipates future growth.

The UgoWork team accompanying you in your energy transition journey consists of an account manager who serves as your single point of contact, along with a customer success manager (CSM), who acts as an advocate for your goals and strategic partner to ensure fast time-to-value. They are backed by a team of mechanical, software, and electrical engineers, product specialists, quality assurance experts and a technical training team. This team is standing by to ensure that your unique situation receives the necessary support, guaranteeing a positive and seamless introduction of UgoWork solutions into your operations.

Explore this article that delves deeper into the role of Customer Success Managers in driving your success through data analytics.

You will meet the people who will participate in your plan and be invited to freely express any questions, concerns, or hesitations in order to get accurate, knowledgeable feedback.

Rigorous planning, mapping, budgeting and scheduling

Once we agree on a tentative plan, our team of engineering and energy experts create a package that includes:

- Calculating the total cost of ownership (TCO) of the initial power infrastructure

- Outlining the main Key Performance Indicators (KPI)

- Performing an application survey and preliminary site layout

- Drafting a cost estimate based on initial assumptions from your site survey and data sample

- Estimating project schedule and timeline

- Proposing financing options and details regarding potential government grants and incentives

3. Proof of concept: Unveiling the benefits of lithium-ion batteries in your operations

The next crucial step to truly see the benefits of lithium-ion batteries in action for your material handling equipment (MHE) fleet is to perform a proof of concept at your site with your operations and operators involved. At UgoWork, we believe that experiencing the technology firsthand is the most effective way to make an informed decision. During the battery trial, our energy experts will:

- Install lithium-ion batteries: We will replace a select number of lead-acid batteries with lithium-ion batteries in your forklift fleet, allowing you to see the immediate impact on performance and efficiency.

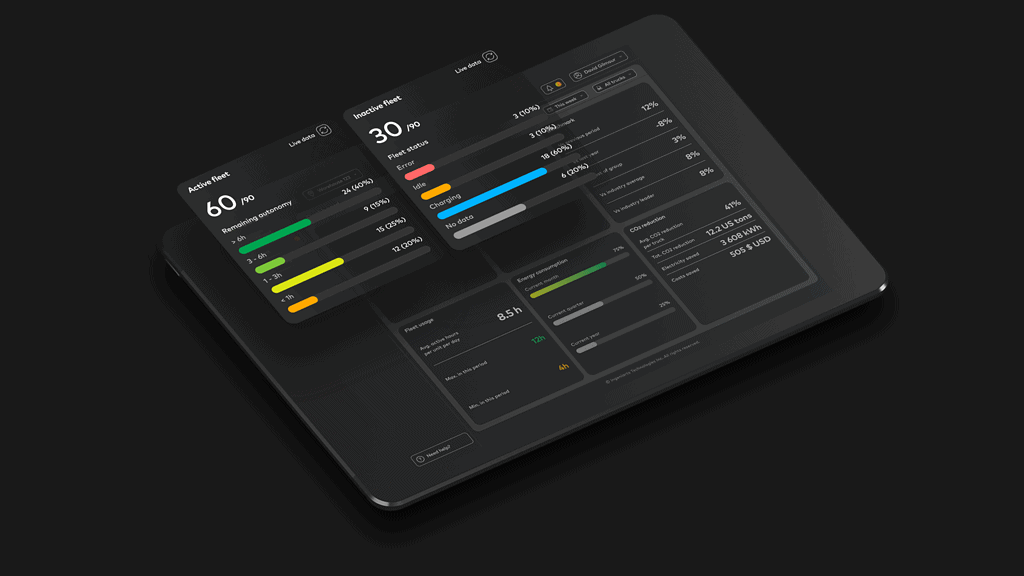

- Monitor and collect data: We will closely monitor the MHE fleet’s performance and collect valuable data on factors like energy consumption, charging times, and overall productivity.

- Conduct operator training: Our technical training team will conduct training sessions with your operators to ensure they are familiar with the new battery technology and understand its optimal usage.

- Analyze results: Our team will analyze the data collected and present comprehensive reports that showcase the benefits of lithium-ion batteries in your specific operations, highlighting factors like increased uptime, reduced maintenance costs, and improved overall safety.

- Address your queries: We will schedule a meeting with you and your team to address any questions or concerns that arise during the proof of concept and provide clarity on how the transition to lithium-ion batteries aligns with your company objectives and budget.

By performing a proof of concept at your site, you’ll gain real-world insights into the advantages of lithium-ion batteries tailored to your unique operations, ensuring that you can make a confident and informed decision about electrifying your MHE fleet. We aim to provide a seamless and successful integration of UgoWork solutions into your operations, and we are committed to supporting you every step of the way. Get ready to embrace a cleaner, safer, and more efficient future with UgoWork’s lithium-ion battery solutions for your material handling needs.

The steps we take provide the knowledge you need to understand how electrifying your fleet will impact your budget and operations; there is no obligation to move forward at this point.

4. Deployment, onboarding and optimization

Should you decide to move forward with UgoWork in your transition to lithium-ion batteries to power your fleet after the proof of concept, you will embark on a structured and optimized workflow designed to maximize the benefits of your new power source.

- Deployment: Your dedicated Customer Success Manager will provide guidance on getting the optimal shop floor layout mapped and electrical infrastructure designed according to the operation pattern. In parallel, we will make sure to certify your local service partner so that they can manage commissioning and service.

- Onboarding: Upon delivery of the first units, our energy experts will perform onsite training for your operators and managers, establish best practices, and configure relevant dashboards and reporting so that you are all set to hit your KPIs.

- Optimization: From that point on, our team will continuously monitor your fleet activity, measure various data points and provide recommendations to optimize your energy usage and asset management. We will also guide you through every step of the product’s lifecycle, including repurposing and recycling.

Should you add lithium-ion batteries to your fleet?

At this point, you should have sufficient information to make informed decisions regarding testing lithium-ion batteries for your forklift fleet and/or the charging infrastructure required for successful lithium-ion integration. Whether you have a medium-sized fleet at a single site or a large multi-site deployment, the process can take from three months to two years.

If you are considering incorporating UgoWork lithium-ion battery solutions into your fleet, we strongly encourage you to request a site assessment and initiate the mapping process.

With experience in infrastructure projects in various sectors, we have the expertise to provide a non-biased, third-party plan to proceed without the pressure of selling a particular brand or product. We recommend what will work best for you and the success of your business.

While this new technology may feel overwhelming, it doesn’t have to be intimidating.

If you have questions about how to get started with advanced charging using the UgoWork charging infrastructure, contact us.

Thank you for checking out the UgoWork Solutions blog. To stay up to date with technologies, developments and trends about clean energy, be sure to visit our site regularly so you don’t miss a thing!