Lithium-ion forklift batteries: It’s what you don’t see that costs you

When you’re managing a warehouse or distribution center, there’s no shortage of things to keep your eye on when it comes to material handling equipment. Throughput. Downtime. Operator safety. Energy costs. The list goes on.

It’s easy to assume your forklift batteries are just another line item—until they’re not.

For many operations, the battery is the one component that nobody really wants to think about…until it causes a slowdown. Or worse, a shutdown. By the time that happens, it’s rarely just one thing; it’s a stack of small details that didn’t seem to matter at the time: poor charging behaviour by operators, a battery plugged in the wrong charger, a battery that can’t handle temperature swings, a lack of insight into each battery’s state of health.

Oh, and when things go wrong, maintenance managers are confronted with the inevitable: service reps from multiple vendors who don’t pick up the phone or point fingers at each other without solving problems.

That’s the real cost of a “good enough” forklift battery. And it’s why more companies are taking a closer look at what powers their lift truck fleets.

It’s not just a forklift battery. It’s the entire ecosystem that powers it.

One of the biggest disconnects in the industry today is how energy systems powering your forklifts are treated like a plug-and-play accessory. But your battery isn’t a standalone component. It’s the heart of your truck, and everything around it depends on how well it performs.

At UgoWork, we don’t just manufacture next-generation lithium-ion lift truck batteries. We offer a complete energy solution designed in-house. That includes the pack design, the harnesses, the thermal management, the software to monitor the batteries’ status, and the charging infrastructure. Every element is built to work together.

Why does that matter?

Because when a truck doesn’t start, you don’t have time to play the guessing game. Was it the charger? The battery? The firmware? Misuse by an operator? When every component comes from a different supplier, figuring that out can cost days. Maybe weeks.

With a fully integrated battery solution, you get faster answers from one partner, fewer battery issues, and a team that owns the support.

UL Listed. OEM approved. Proven in the field.

Compliance isn’t exciting until you realize it protects your forklift fleet and throughput.

Every UgoWork battery is UL Listed and approved by major OEMs. That’s right. All of our products meet rigorous UL certification standards. We also work directly with leading forklift manufacturers to ensure full approval for specific models and real-world use cases.

Our forklift batteries feature a proprietary design with lithium cells from a renowned Tier-1 supplier and are packed by one of the largest automotive packers in the world, and include a robust thermal management system (TMS).

UgoWork batteries are proudly assembled in North America, where we manage every critical aspect of the system, from pack design and software to final assembly. That level of vertical integration means tighter quality control. Thanks to brutal battery testing and inspections before they leave our facilities, our batteries have been running in demanding environments for up to ten years.

One charging station for all your forklifts

We built UgoWork’s charging system to eliminate the hassles associated with conventional forklift battery charging processes. One universal charging station supports all battery voltages in your fleet. There is no wall clutter or huge battery rooms. Our EV-grade, automotive-grade connector interfaces with the battery’s charging interface, so the battery’s SB connector never has to be disconnected from the truck’s. There is no handling of the battery to be charged. Operators plug the EV connector into the UgoWork battery in a motion as natural as a handshake, see the state-of-charge indicator light up, and get on with their day.

It’s intuitive. It’s scalable. And it’s one less thing to worry about as your fleet evolves.

Lithium-ion forklift batteries: Engineered for what’s next

Every battery has a lifecycle. But that doesn’t mean the enclosure should go to waste.

Our packs are designed with longevity and flexibility in mind. When it’s time to refresh the cells, the casing and core system stay in place. That’s less waste and more value from your original investment.

We also designed our batteries with modular counterweights. That means if your equipment needs change (say, you move the battery to a truck with a different compartment size), you don’t need a new battery. You just swap the counterweight and move on.

UgoWork’s batteries don’t feel the heat or cold

A lot of batteries work well in a showroom. Fewer hold up in a sub-zero F&B warehouse or under the heat of a manufacturing floor.

We built our thermal management system (TMS) to handle both extremes. Whether you’re running lift trucks with high peak loads or sit-down counterbalance forklifts in cold storage, UgoWork batteries keep their cool—literally.

And we don’t just say that. Years of field data from facilities across North America prove that the UgoWork batteries operate safely and efficiently in harsh, real-world material-handling applications.

Real-time insights without the headaches

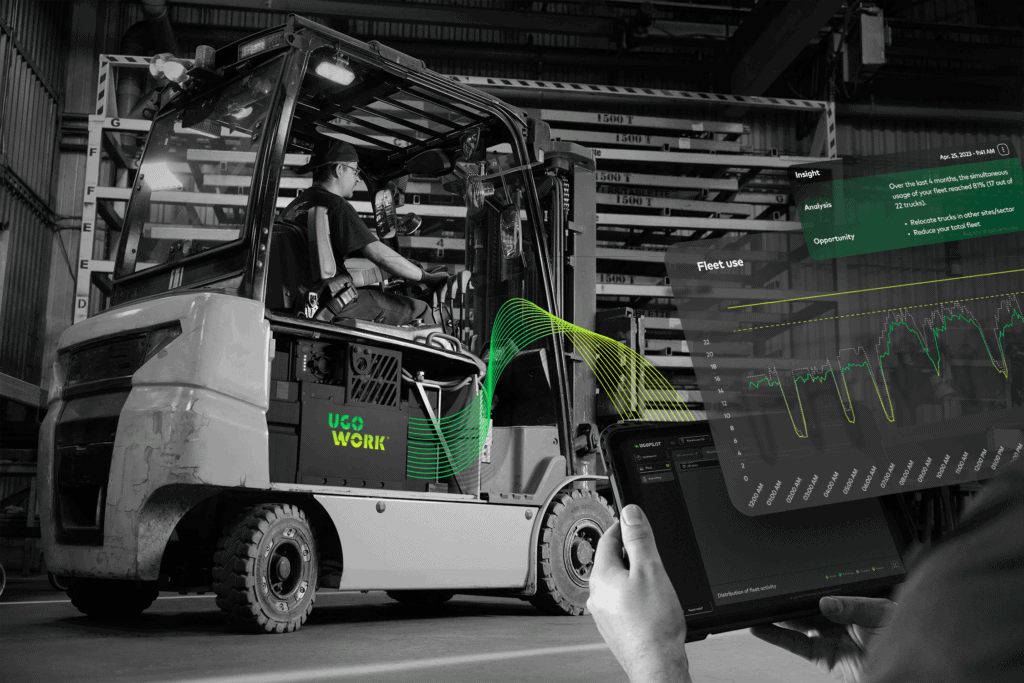

You don’t need another dashboard collecting dust. You need information that’s actually useful and easy to act on.

That’s what UgoPilot delivers.

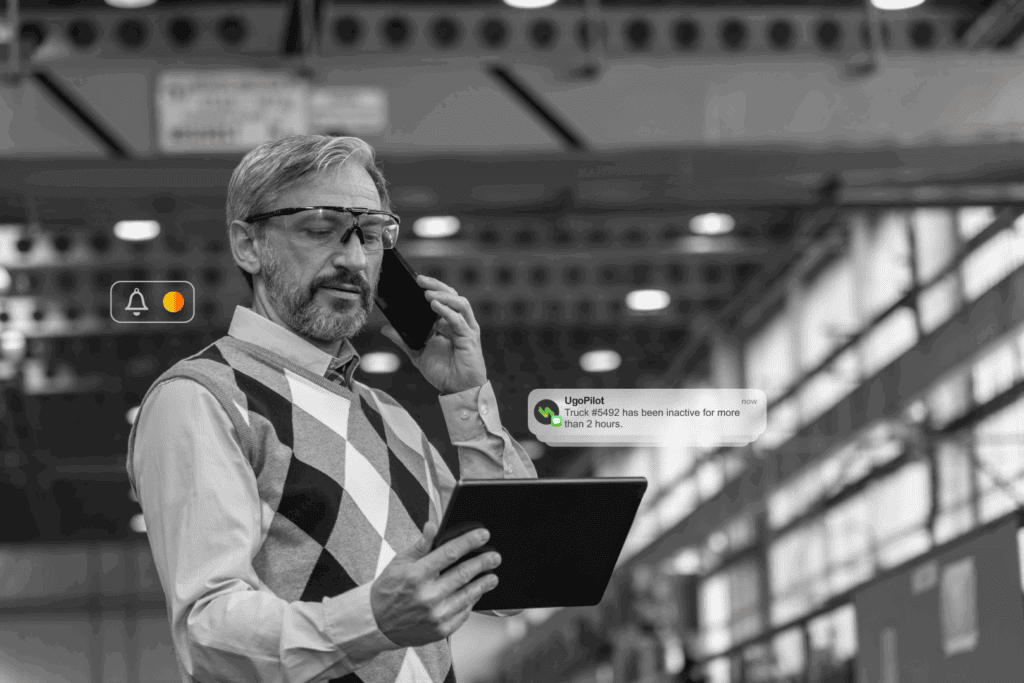

It’s our built-in battery intelligence platform that lets you see how your battery is performing at a glance. Need to know how many hours a battery’s been running? Check. Curious if your team is charging efficiently? It’s all there. Whether you’re on the shop floor or in the office, UgoPilot gives you live data as to your battery fleet’s condition. Maintenance managers even get alerts on their phones if a battery is about to malfunction.

It’s battery health and usage patterns all in one place. The bonus? All the info is there in easy-to-understand reports. No PhDs required.

Whether you’re managing uptime or keeping equipment running smoothly, you can’t afford to waste time watching a dashboard. UgoPilot monitors your fleet in real time and notifies you only when something needs attention. Set alerts for conditions like low state of charge, inactivity, or lost communication, and get notified by email or SMS before small issues become costly downtime.

In a nutshell, instead of reacting to problems, you can prevent them from occurring at all.

One team. One system. One call.

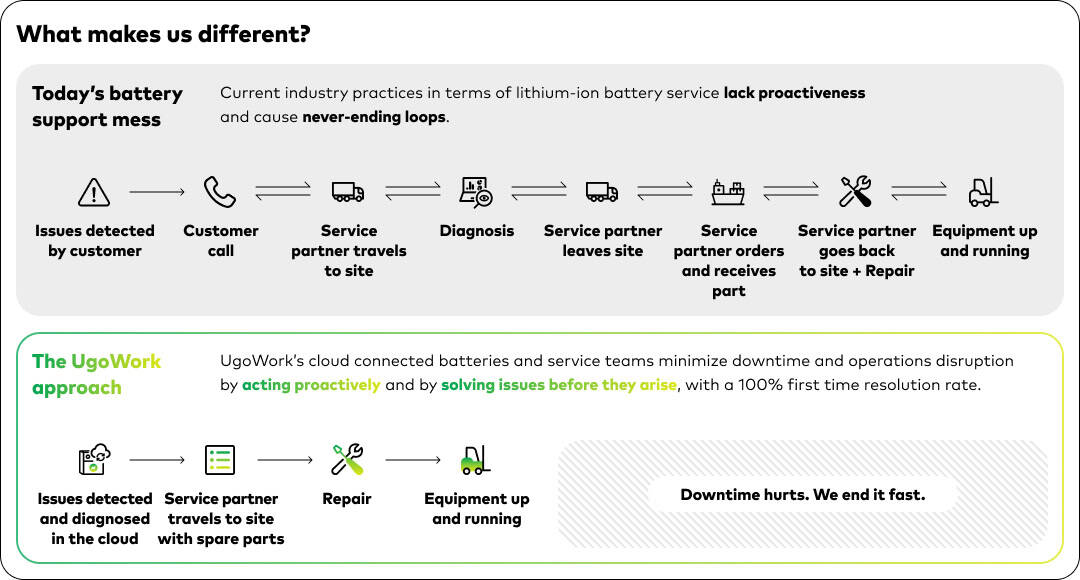

Ask any operations manager what they dread most when equipment goes down, and it’s rarely the repair itself. It’s the process. The back-and-forth between vendors. The finger pointing. The “not our issue” emails.

We’ve heard the stories. And we’ve built UgoWork to be the opposite of that.

When you partner with us, your battery and charger come from the same team. Our support staff knows the entire system inside and out. There’s no need to escalate across three vendors or wait for an overseas callback. You get answers from energy experts who know your setup and can get you back up and running fast.

What’s more, we provide extensive training, support tools, and spare parts to material handling teams and their forklift battery dealers. If something does come up, there are no repeated truck rolls with different technicians. Maintenance managers or their dealer techs get fast, informed support from our experts who know exactly what to look for and how to fix it the first time.

Finally, UgoWork’s Customer Success team oversees your lift truck battery performance levels through battery state of health monitoring and support for forklift fleets. This enables your operations crew to receive tailored recommendations on how to save energy and even right-size your forklift fleet. That can mean hundreds of thousands of dollars saved each year.

With UgoWork on your side, you really do get what you pay for

With forklift battery investments, it’s tempting to focus on upfront cost. But as every fleet manager eventually learns (the hard way), the real price of a forklift battery isn’t what’s on the invoice. It’s what happens after the trucks hit the floor. Unreliable charging, batteries that falter in the cold, missed performance data, and delays when something breaks. Those costs add up in downtime, maintenance hours, and frustration.

UgoWork was built to eliminate those hidden costs. Everything we make is designed for performance, so you won’t have to babysit your batteries. It’s not about a battle between spec sheets. It’s what your battery vendor commits to do after the deal is done. It’s about peace of mind. And when you’re running a fleet that can’t afford to stop, that peace of mind is worth every penny.

UgoWork batteries pay for themselves.