Forklift battery costs: Why total cost of ownership and efficiency matter more than the price tag

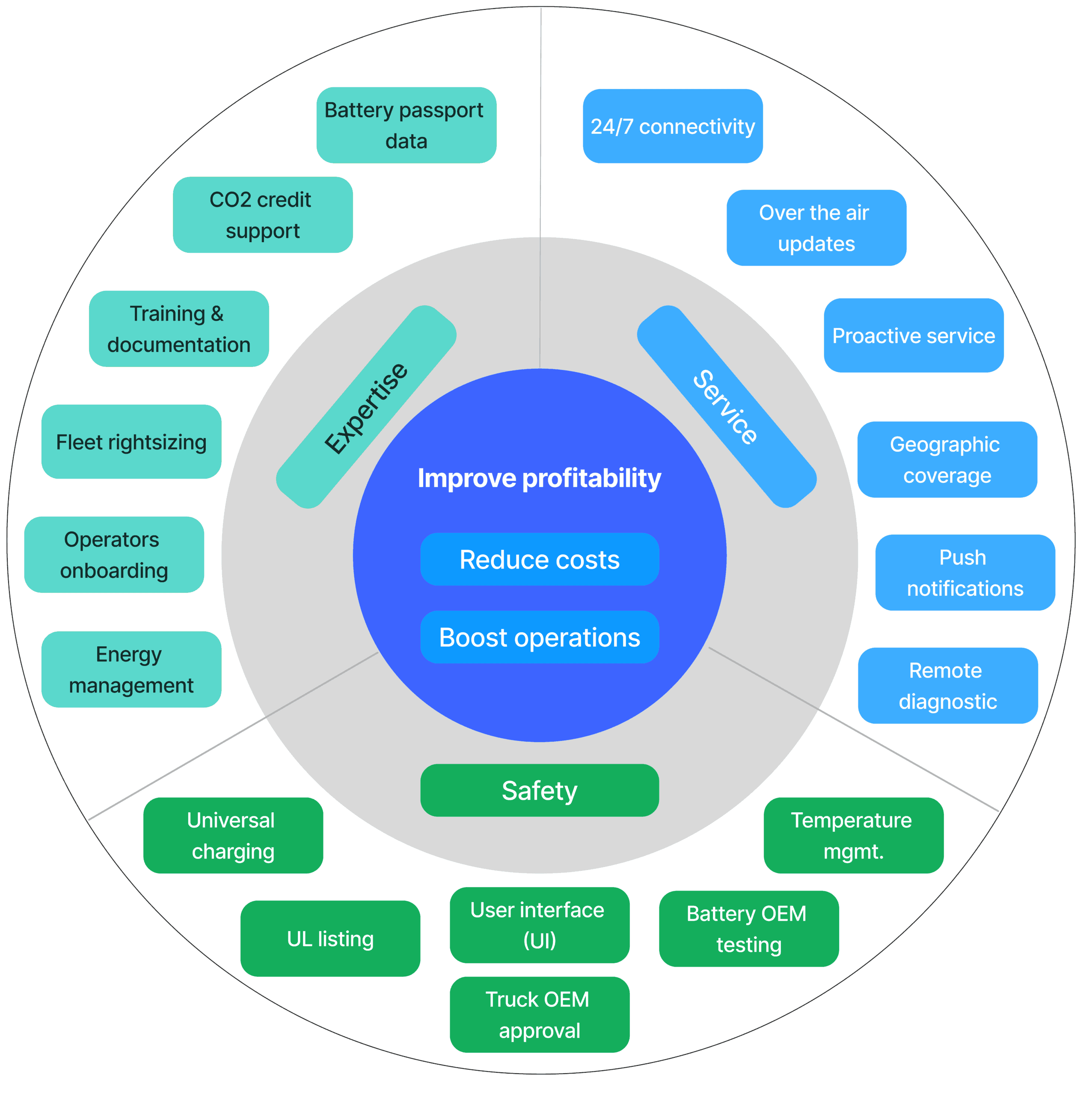

When your lift truck batteries die mid-shift, every minute wasted is money straight out of your pocket. Too many maintenance and operations managers stop at a forklift battery’s sticker price and glossy spec sheets—only to discover that battery downtime, replacement cycles, charger upgrades, and surprise service calls can double, even triple, the real cost of that “budget” lift truck battery. If you’re still making decisions based on numbers on paper, you’re leaving productivity and profit on the table.

It’s time to look beyond the glossy marketing and same ol’ same ol’ sales pitches you’ve heard before. Check out our latest recorded webinar, Lithium-ion battery showdown: Features, safety and value for your money.

UgoWork pulls back the curtain on the total cost of ownership of forklift batteries—and shows how next-generation lithium-ion batteries can actually pay for themselves. We’re not joking.

We’ll walk you through a real life situation in which an Operations Manager had to select a power solution and decide which lithium-ion provider to go to. You’ll also learn which OEM and UL safety certifications matter, how real-time fleet data keeps you ahead of lift truck battery failures, and why proactive support isn’t a luxury—it’s your lifeline to 24/7 uptime.

Ready to stop chasing short-term savings and start locking in long-term gains?