Energy-as-a-Service (EaaS) in material handling and logistics: Unlocking unprecedented productivity gains and cost savings

Energy-as-a-Service (EaaS) in material handling and logistics: Unlocking unprecedented productivity gains and cost savings

In order to overcome tremendous productivity, labor and cost challenges, the logistics industry is currently undergoing a massive digital transformation, with new technologies and approaches that completely change the game in material handling.

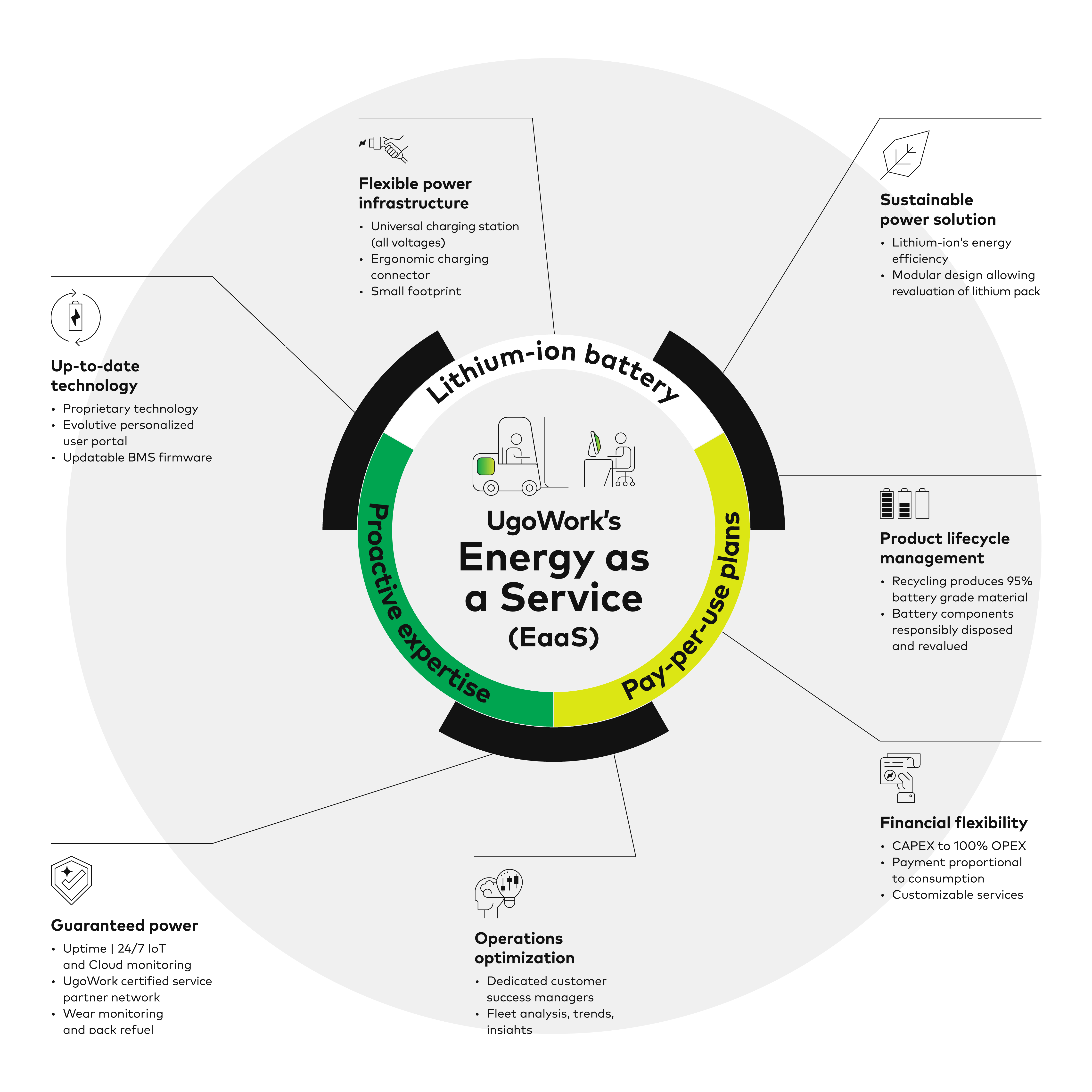

One such innovation is Energy-as-a-Service (EaaS) in material handling. EaaS is a delivery model that brings together hardware, software and services. End-to-end EaaS solutions in the material handling industry, like those offered by UgoWork, are proving to be critical in helping businesses cut costs—all while boosting team efficiency and throughput without added staff.

Let’s take a look at the different components of an EaaS solution and the advantages of implementing one in a company’s logistics and material handling operations.

Reducing material handling costs through new forklift technologies

Material handling costs often rise due to legacy forklift equipment and a lack of understanding of the total cost of ownership (TCO) managing a forklift fleet. For example, traditionally, forklifts are powered by lead-acid batteries or propane. However, advances in battery technologies are demonstrating that lithium-ion batteries offer much better charging speed, energy efficiency, depth of discharge, maintenance optimization, and lifespans than their lead-acid and propane counterparts.

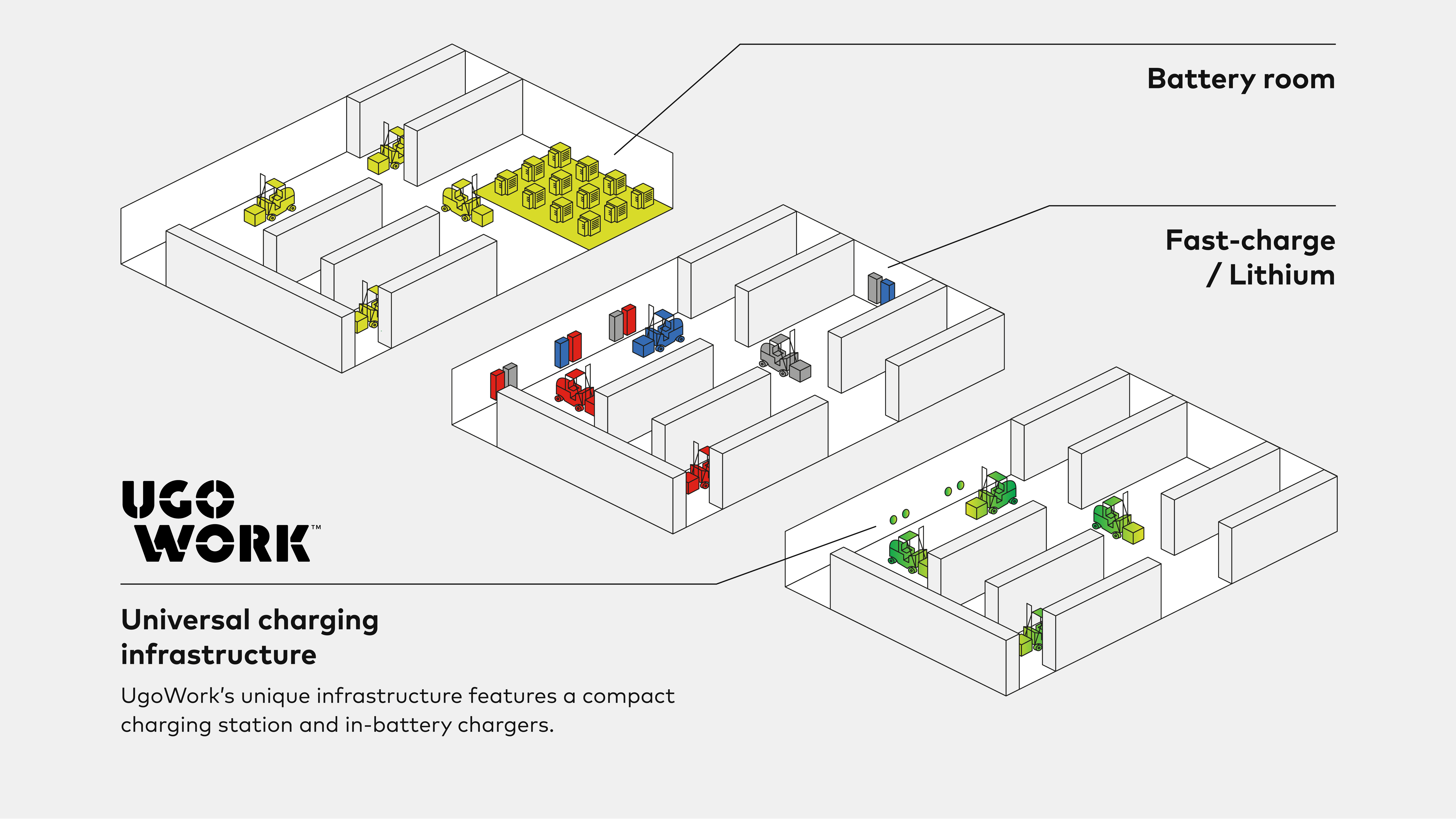

Lithium-ion batteries for industrial trucks can come with a universal charging station, which means vehicles of all voltages can be charged with power infrastructure that takes up less space (smaller footprint) than conventional chargers for lead-acid batteries.

How do lithium-ion batteries factor into the foundation of an EaaS model for material handling?

UgoWork offers versatile payment options depending on companies’ distinct needs. Some may prefer acquiring total ownership of the lithium-ion batteries, while others opt for pay-per-use plans that are proportional to energy consumption to reduce upfront CAPEX costs. This flexibility means material handling teams have better control over the costs associated with operating a forklift fleet.

It is also important to keep in mind that with conventional approaches, if fleet operators transition to new technologies, they accept the risks associated with technological products that they are not expert with. Moreover, the financials are calculated based on an amortization period equal to the useful life of the solution claimed by the manufacturer and a projected throughput. With EaaS, the risk is minimal: they simply pay for what they use.

Finally, innovations in battery technologies run at a rapid-fire pace. Suppliers that guarantee their products for 10 years do not take into account these advances, which inevitably leaves many customers grappling with legacy solutions without any means to upgrade and forgo extra costs. An EaaS approach provides businesses with a flexible and affordable option to ease into the adoption of new technologies, ensure they work with the latest solutions, and benefit from the guarantees that EaaS models provide. This is risk management at its best.

EaaS solutions: Guaranteed uptimes thanks to “always-on” services and optimization

Contrary to many suppliers, which simply offer material handling equipment and after sales service if something goes wrong, EaaS partners take operations optimization to a whole new level.

Because the forklift batteries are connected via a robust IoT and cloud-based platform, they are constantly being monitored to detect anomalies or problems before they cause any equipment damage, downtimes to material handling operations, or accidents that could jeopardize operator safety.

EaaS is akin to managed fleet services; teams gain access to comprehensive analytics and dashboards to pinpoint trends, carry out predictive and preventative maintenance, and have greater visibility in the batteries’ state of health, performance levels over time, etc.

What’s more, for maximum insights, EaaS partners like UgoWork assign customer success managers to each customer to perform regular analyses and benchmark the forklift fleet’s overall performance against industry leaders. The advantages of having dedicated customer success managers include:

- Experts to analyze and provide recommendations to eliminate certain maintenance and energy costs

- Consulting to maximize the use of lithium-ion batteries

- Tips to optimize truck allocation and scheduling throughout the warehouse

- And much more

Many EaaS clients, along with their customer success teams, can actually reduce the number of trucks, minimize downtimes, and optimize their energy consumption with access to in-depth analytics.

A case in point? Thanks to the monthly operational data gleaned from their EaaS contract, one of UgoWork’s clients, a major player in the North American fruit and vegetable market, was able to identify that their reach trucks were used for more travel than they should have and not enough to lift warehouse items. The warehouse material handling team improved operations by compensating traveling with pallet jacks so that reach trucks could concentrate their efforts on vertical movement. As a result, they could maximize the global energy throughput of the fleet, reduce the reach fleet size, and ultimately save costs.

Product lifecycle management made easy with EaaS

Typically, material handling and logistics teams put a great emphasis on the beginning of a high-tech product lifecycle, integrating new technologies and extending the lifespan of equipment.

But what happens when the equipment comes to the end of its useful life? End-of-life extension and product retirement are becoming even more important with electric vehicle batteries. With new legislation coming into effect in many countries, ESG compliance, and adhering to the upcoming battery passport system, as proposed by the Global Battery Alliance, material handling managers will have no choice but to re-evaluate how they get rid of their forklift batteries.

EaaS companies are fast becoming a viable solution to help the material handling and logistics industry to identify the best ways to recycle, revalorize or sustainably dispose of EV batteries, regardless of the technology. EaaS providers work with networks of credible partners, for example, to recycle forklift batteries and actually produce 95% battery-grade material. Not only does this foster a circular economy but it also helps businesses hit their sustainability targets.

EaaS in material handling: A scalable, future-proof model

With EaaS, material handling and logistics teams are not pigeon-holed in adopting a solution and remaining with it forever. As EaaS providers continuously innovate and fine-tune their technologies, their customers can evolve with them.

If new functionalities are added to the EaaS’ software platform, customers can take advantage of them. Has the company developed a battery that offers even more energy savings? Customers can upgrade their fleets as they see fit. This notion of scalability and agility means material handlers and logistics companies don’t have to overhaul their entire operations at once—but they can see the immediate benefits even if they phase their deployments.

Interested in learning more about how EaaS may be right for your material handling and logistics operations? Contact UgoWork today.